Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

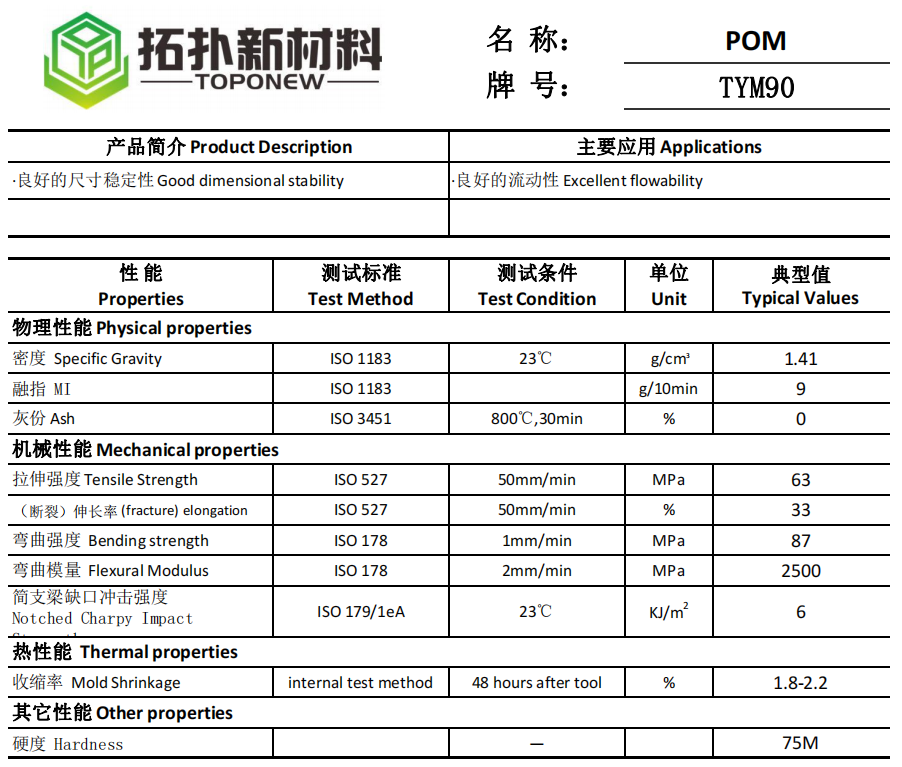

POM TYM90

MI: 9g/10min

Hardness: 75M

(Custom materials available according to your Technical Data Sheet)

- Les détails du produit

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

Technical Data Sheet of POM TYM90 POM Plastic Granules

POM Wear Resistance POM Plastic Raw Material Granule

What is POM Material?

POM, also known as Polyoxymethylene, is a high-performance engineering plastic that belongs to the family of crystalline thermoplastics. It is commonly available in the form of POM pellets, which are small granules used as raw material for various manufacturing processes.

POM (polyoxymethylene, also known as polyacetal or acetal) is generally a highly crystalline thermoplastic. It has good mechanical properties, high dimensional stability, and wear behavior. Also, high strength and low coefficient of friction are significant and advantageous characteristics of POM plastics. The POM is recyclable, and the main properties are maintained in the recycled POM (R-POM) if properly treated.

The Feature of Plastic Pom Resin/Pellet/Granule POM

POM plastic material specification/ POM material properties

- Appearance: POM raw material appearance is light yellow or white translucent or opaque powder or granules. Hard and dense, similar to ivory, the product surface is smooth and lustrous.

- Flammability: Flammable, after the fire can continue to burn. Its oxygen index is only 14-16. the upper end of the flame is yellow and the lower end is blue.

- Breathability: The permeability of POM raw material is very small, only a fraction of PE.

- Shrinkage: The high crystallinity of POM raw material leads to shrinkage of up to 2% to 3.5%.

- Mechanical properties: POM raw material has good mechanical properties, high modulus of elasticity, low coefficient of friction and stability, good wear resistance, and good self-lubrication. Hardness and stiffness are very high, very close to the metal.

- Heat resistance: POM raw material heat resistance is poor and easy to degrade under the molding temperature release acetaldehyde. Usually, in the granulation process to add stabilizers are. Heat deformation temperature is high, homopolymerization degree is high at 136°C, and copolymerization degree is 110°C. In 220 above ℃ decomposition of formaldehyde gas, can be used in 140 ℃ short-term, and long-term use temperatures of -40-100 ℃.

- Excellent mechanical properties over a temperature range upto 140°C, down to -40°C

- High tensile strength, rigidity, and toughness (short-term)

- Low tendency to creep (as compared to nylon) and fatigue (long-term). Not susceptible to environmental stress cracking

- High degree of crystallinity and excellent dimensional stability

- Excellent wear resistance

- Low coefficient of friction

- Good resistance to organic solvents and chemicals (except phenols) at room temperature

- Low smoke emission

- High gloss surfaces

- Low moisture absorption

POM exhibits excellent mechanical properties, such as high stiffness, strength, and dimensional stability. It also possesses low friction coefficient, good wear resistance, and is resistant to chemicals and solvents. With its low moisture absorption rate and high heat resistance, POM is suitable for applications requiring durability and precision.

What are Plastic Resin Pellets used for?

Plastic resin pellets, including POM pellets, are widely used as feedstock in injection molding and extrusion processes. They are melted and shaped into various components and products, such as gears, bearings, fasteners, electrical connectors, automotive parts, and consumer goods. POM pellets allow for precise molding and can be easily processed into complex shapes.

As a POM material manufacturer in the industry, we are dedicated to providing high-quality POM pellets that meet your specific needs.

We understand the importance of having comprehensive information about the material you require. You can also kindly tell us what color would you like, material POM black, or other colors are available. To ensure we provide you with the most accurate and relevant quotation, we kindly invite you to share the Technical Data Sheet (TDS) or any specific property requirements for the POM plastic pellets.

POM stands for Polyoxymethylene, which is also known as Acetal or Polyacetal. It is a high-performance engineering thermoplastic known for its excellent mechanical properties, low friction, and dimensional stability. The composition of POM includes:

-

Polymer Backbone: The main component of POM is the polymer chains consisting of repeating units of oxymethylene (-O-CH2-) linked together. These chains provide POM with its structure and properties.

-

Methyl Groups: POM contains methyl groups attached to the oxygen atoms along the polymer chain. These methyl groups contribute to the polymer's chemical and thermal stability.

-

Additives: POM resins can include various additives such as stabilizers, lubricants, and fillers to enhance specific properties or improve processability.

Key properties of POM include high stiffness, excellent wear resistance, low friction, good chemical resistance, and dimensional stability. POM is commonly used in applications where high mechanical strength and precision are required, such as gears, bearings, snap-fit assemblies, automotive components, and medical devices.

POM composite refers to a material that is a blend of Polyoxymethylene (POM) with other substances or reinforcements to enhance or modify its properties. The addition of these additives can help tailor the material to specific application requirements. Some common types of POM composites include:

-

Filled POM Composite: POM can be reinforced with fillers such as glass fibers, carbon fibers, or minerals to improve strength, stiffness, and dimensional stability. These filled POM composites exhibit enhanced mechanical properties compared to unfilled POM.

-

Lubricated POM Composite: POM can be compounded with lubricating additives like PTFE (polytetrafluoroethylene) to reduce friction and improve wear resistance. These lubricated POM composites are commonly used in applications where low friction and good wear properties are crucial.

-

Impact-Modified POM Composite: By incorporating impact modifiers into POM, the toughness and impact resistance of the material can be improved. Impact-modified POM composites are used in applications where resistance to mechanical shock or impact is essential.

-

Heat-Stabilized POM Composite: To enhance the thermal stability of POM and improve its performance at elevated temperatures, heat stabilizers may be added to the material. Heat-stabilized POM composites are suitable for applications that require good thermal resistance.

-

Electrically Conductive POM Composite: POM can be formulated with conductive additives to create electrically conductive composites. These materials are used in applications where static electricity control or EMI (electromagnetic interference) shielding is required.

Overall, POM composites offer a wide range of properties tailored to specific applications, providing designers with flexibility in material selection to meet diverse performance requirements.

Download

-

拓扑新材料 POM TYM90.pdf

Download 拓扑新材料 POM TYM90.pdf